Microwatt welcomes Nexxis as our new partner, driving innovation in advanced inspection solutions.

Calgary, Canada (October 1st, 2025)

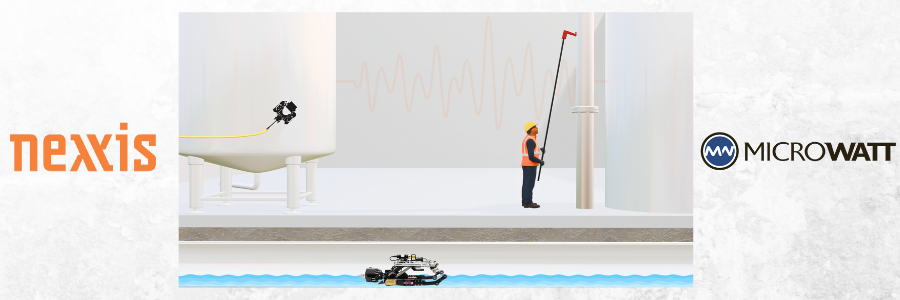

Microwatt is excited to announce our partnership with Nexxis, an Australian-based leader in robotic and NDT inspection solutions. Nexxis designs and delivers modular, outcome-focused technologies—including advanced robotic crawlers, inspection cameras, and sensor systems—that thrive in harsh, hard-to-access environments. Their solutions are trusted globally for helping operators reduce downtime, improve data accuracy, and safely inspect assets without compromise.

About Nexxis

Nexxis specializes in designing modular robotic systems engineered for hazardous and hard-to-reach environments. Their technologies are designed to enhance safety, efficiency, and data accuracy across various sectors, including oil & gas, energy, mining, and infrastructure. By combining innovation with practical field knowledge, Nexxis has become a trusted partner for industries that require dependable and flexible inspection tools in the most demanding conditions.

Expanding Our Inspection Solutions

Our new partnership with Nexxis brings cutting-edge robotic and NDT inspection systems into Microwatt’s portfolio. For our customers, this means access to versatile, modular tools that address some of the toughest inspection challenges—whether confined space, submerged, vertical, or high-flow environments. By partnering with Nexxis, Microwatt strengthens its role as a provider of complete inspection solutions. From ultrasonic thickness testing to laser profiling and 3D mapping, these systems give operators the confidence to tackle inspections safely, efficiently, and with greater accuracy.

Advancing Ultrasonic Testing (UT) Capabilities

Through this partnership, Microwatt will also highlight Nexxis’ expertise in Ultrasonic Testing (UT) — a proven non-destructive testing (NDT) method that delivers precise data without compromising asset integrity.

As outlined in Nexxis’ research:

- In pipeline and thickness inspections, Nexxis emphasizes the importance of defining the problem first and choosing the right UT tool second. This approach ensures that inspections are solution-driven, efficient, and aligned with operational priorities.

For composite structures, UT provides accurate, non-intrusive insights into thickness, flaws, and bonding integrity — ensuring reliability without damaging materials.

Meet the Snowcat Crawler

The Snowcat Crawler is a flagship Nexxis innovation, engineered for reliable mobility in confined spaces and submerged environments. It is a rugged magnetic crawler engineered to deliver high-definition remote visual inspections in confined environments. Modularity is at the core of Snowcat’s design. From 3D LiDAR mapping for precise point cloud visualization to manipulator tools and NDT sensor compatibility, Snowcat adapts to diverse inspection tasks. Whether in tanks, vessels, ship hulls, or offshore pipelines, this crawler reduces the need for confined space entry and working at height.

With its compact design, customizable payloads, and ability to operate in extreme conditions, Snowcat delivers reliable inspection capabilities where traditional methods fall short. Its adaptability makes it an invaluable tool for industries facing complex inspection requirements.

Other Solutions Now Available:

- Panther Pipe Crawler A modular system designed for adaptability, Panther configures inline, parallel, or with magnetic attachments—making it ideal for pipelines pipelines from 8” diameter.

- Hellcat Crawler A high-endurance system for extreme environments and large diameter pipelines up to 1km length, Hellcat can integrate dual UT probes for advanced ultrasonic testing, high-resolution cameras, and optional laser scanning for unmatched precision.

- VETOL Robot Purpose-built for vertical pipeline inspections, VETOL features modular payloads, HD imaging, fiber-optic tethering, and compatibility with advanced NDT sensors for deeper insights.

Delivering More Value to Industry

By partnering with Nexxis, Microwatt strengthens its role as a provider of complete inspection solutions. From ultrasonic thickness testing to laser profiling and 3D mapping, these systems give operators the confidence to tackle inspections safely, efficiently, and with greater accuracy.

Get the Latest Updated

We’re just getting started with our partnership with Nexxis, and there’s much more to come.

Stay Connected on LinkedIn