The TCMH 0450 is TRICOR’s High Pressure Coriolis Mass Flow Meter, offered in three pressure ratings: 6,000 psi, 10,000 psi or 15,200 psi. The material choices for the U-shape tubes are either 316 stainless steel for chemical injection applications or Sandvik® Alloy HP 160, chosen to eliminate hydrogen embrittlement, such as in Hydrogen fueling stations.

| Nom. Flow Rates: | |

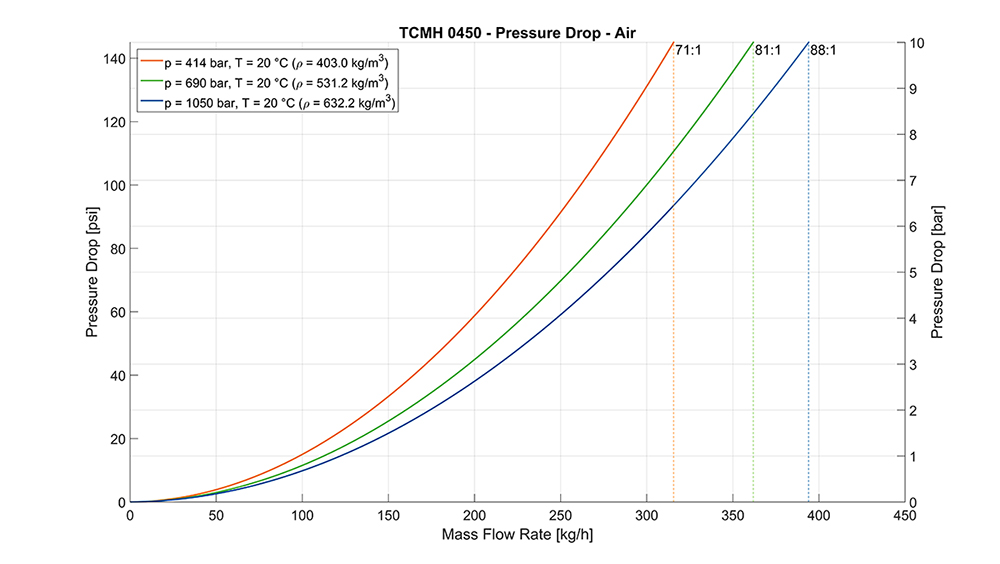

| @ 20°C air, pressure drop 10 bar: | 394 kg/h @ 1050 bar, 14.5 lb/min @ 15200 psi |

| 362 kg/h @ 690 bar, 13.3 lb/min @ 10000 psi | |

| 316 kg/h @ 414 bar, 11.6 lb/min @ 6000 psi | |

| @ 20°C H2, pressure drop 50 bar: | 254 kg/h @ 1050 bar, 9.30 lb/min @ 15200 psi |

| 240 kg/h @ 875 bar, 8.80 lb/min @ 12690 psi | |

| 222 kg/h @ 690 bar, 8.15 lb/min @ 10000 psi | |

| 184 kg/h @ 414 bar, 6.75 lb/min @ 6000 psi | |

| Pressure Rating: | |

| TCMH 0450-HC-SPPS (or -SPMS): | 1050 bar, 15200 psi |

| TCMH 0450-HC-SRPS (or -SRMS) | 690 bar, 10000 psi |

| TCMH 0450-HC-SSPS (or -SSMS): | 414 bar, 6000 psi |

| P (1.4404/AISI 316L) = NACE compliant, M (HP160) = not NACE compliant. | |

| Connection: | 3/8” Autoclave (MP), other connections available |

- Robust for long life service

- Delivers increased productivity

- Integrated pressure compensation

- Minimal pressure effects despite dynamical pressure changes

- Customised installation length

- Considerable cost savings for installation

- Excellent repeatability

- Delivers increased product quality

- Optional net oil functionality

- Increased well efficiency

| NOM. FLOW RATES | |

| @ 20°C air, pressure drop 10 bar: | 394 kg/h @ 1050 bar, 14.5 lb/min @ 15200 psi |

| 362 kg/h @ 690 bar, 13.3 lb/min @ 10000 psi | |

| 316 kg/h @ 414 bar, 11.6 lb/min @ 6000 psi | |

| @ 20°C H2, pressure drop 50 bar: | 254 kg/h @ 1050 bar, 9.30 lb/min @ 15200 psi |

| 240 kg/h @ 875 bar, 8.80 lb/min @ 12690 psi | |

| 222 kg/h @ 690 bar, 8.15 lb/min @ 10000 psi | |

| 184 kg/h @ 414 bar, 6.75 lb/min @ 6000 psi | |

| PRESSURE | |

| TCMH 0450-HC-SPPS (or -SPMS): | 1050 bar, 15200 psi |

| TCMH 0450-HC-SRPS (or -SRMS): | 690 bar, 10000 psi |

| TCMH 0450-HC-SSPS (or -SSMS): | 414 bar, 6000 psi |

| P (1.4404/AISI 316L) = NACE compliant, M (HP160) = not NACE compliant. | |

| CONNECTION | 3/8” Autoclave (MP), other connections available |

| ACCURACY | |

| Flow: | ±1 % of reading |

| Mass Repeatability: | ±0.5 % of reading |

| Zero Stability: | 0.45 kg/h, 0.0165 lb/min |

| Temperature: | ±1.8 °F ±0.5 % of reading (±1 °C ±0.5 % of reading) |

| OPERATING CONDITIONS – PROCESS | Customer specific pressure compensation curves on request. |

| Medium Temperature: | -40 °F … +212 °F (-40 °C … +100 °C) |

| Fluid: | Gas |

| Pressure Effect on Sensitivity: | 0.0002 %/bar, 0.000014 %/psi |

| OPERATING CONDITIONS – ENVIRONMENT | |

| Ambient Temperature: | -40 °F … +158 °F (-40 °C … +70 °C) |

| Relative Humidity: | max. 95 % |

| MATERIAL OF CONSTRUCTION | |

| Tubes: | 1.4404/AISI 316L or Sandvik Alloy HP160. |

| 1.4404/AISI 316L = NACE conform, HP160 = not NACE conform. | |

| Manifold: | 1.4435/AISI 316L |

| Housing: | 1.4404/AISI 316L |

| BURST PROTECTION | |

| Rupture Disc: | G1/2” |

| CABLING | |

| Signal Cable Connection: | Push-Pull connector |

| For triple Ex approval (Ex3) | With connector M23 (TCE) and with connector Lemo (TCM), x m cable length (TCC-06-xx). |

| EX CERTIFICATIONS | |

| ATEX (Ex): | Zone 1: Group IIC, T2…T4 |

| ATEX (Exn): | Zone 2: II 3G Ex nA IIC, T2…T4 Gc |

| IECEx (Ex): | Zone 1: Group IIC, T2…T4 |

| cCSAus (Ex1): | Class I, Division 1: Group A, B, C, D, T2…T4 |

| For cCSAus the electronic is only available in aluminum housing. | |

| ATEX + IECEx + cCSAus triple approval (Ex3): | Zone1: Group IIC, T2…T4 and Class 1, Div. 1: Group A, B, C, D, T2…T4 |

| For Ex3 the electronic is only available in aluminum housing. |

TRICOR® Coriolis Technology Ltd.

When you combine decades of experience with truly unique talents, great things can happen. TRICOR engineers have been intimately involved with the development and evolution of Coriolis flow instrumentation since the beginning. In fact, many of the critical patents for Coriolis technology bear our engineers’ names. The TRICOR Coriolis range of globally-certified flow measurement products are designed and engineered in Germany with support teams in the United States and Switzerland. Our state-of-the-art manufacturing facility in Karlsfeld, Germany is equipped with advanced calibration and test equipment that guarantees world-class performance and the highest-accuracy, delivering flow measurement solutions for the most demanding applications.