TRICOR’s Diamond Shape Coriolis Mass Flow Meters range in flow rate from 325 to 3100 kg/hr (12 lb/min) and withstand pressures up to 2900 psi (200 bar). The diamond shape (D-shape) tube design has the best overall performance of any Coriolis tube shape. The mechanical advantages of this design include the best signal-to-noise ratio and reduced effects of external vibrations, thus improving zero stability. Each meter is mechanically balanced to ensure the best in class density measurement and overall performance.

| Mass Flow Rate (max.): | 1550 kg/h, 57 lb/min |

| Volumetric Flow Rate (max.): | 1550 l/h, 6.82 gpm, 234 bbl/d (US) |

| Standard Pressure Rating: | up to 200 bar, 2900 psi |

| Nominal Meter Size: | DN6, 1/4″ |

- Robust for long life

- Delivers increased productivity

- Integrated pressure compensation

- Minimal pressure effects despite dynamical pressure changes

- Customised installation length

- Considerable cost savings for installation

- Excellent repeatability

- Delivers increased product quality

- Option for 345 bar (5000 psi)

- For accurate chemical injection metering

| MEASURING RANGES | |

| Mass Flow Rate (max.): | 1550 kg/h, 57 lb/min |

| Volumetric Flow Rate (max.): | 1550 l/h, 6.82 gpm, 234 bbl/d (US) |

| PRESSURE | |

| Standard Pressure Rating: | up to 200 bar, 2900 psi |

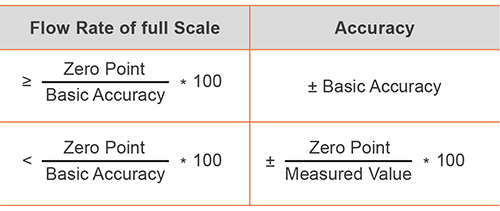

| ACCURACY (LIQUIDS) | Stated flow accuracy combines the effects of repeatability, linearity and hysteresis. |

| Basic Accuracy [Mass flow]: | ±0.1 % of flow rate |

| Mass Flow Repeatability: | ±0.05 % of flow rate |

| Basic Accuracy [Volume flow]: | ±0.15 % of flow rate |

| Volume Flow Repeatability: | ±0.05 % of flow rate |

| Zero Stability: | ±0.01 % of full scale |

| ACCURACY (GASES) | |

| Basic Accuracy [Mass flow]: | ±0.5 % of flow rate |

| Mass Flow Repeatability: | ±0.25 % of flow rate |

| DENSITY | |

| Density Range: | up to 2500 kg/m³, 2.5 g/cm³ |

| Density Accuracy: | Liquids ±1.0 kg/m³, ±0.001 g/cm³ |

| Density Repeatability: | ±0.5 kg/m³, ±0.0005 g/cm³ |

| TEMPERATURE | |

| Process Temperature Range: | Standard: -40 °F … +212 °F (-40 °C … +100 °C) |

| Optional: -76 °F … +392 °F (-60 °C … +200 °C) | |

| Temperature Accuracy: | ±1.8 °F ± 0.5% of reading (±1 °C ±0.5 % of reading) |

| Temperature Repeatability: | ±0.36 °F (±0.2 °C) |

| MATERIAL OF CONSTRUCTION (wetted parts) | |

| Tubes: | 1.4404/AISI 316L |

| Case: | 1.4404/AISI 316L |

| Flow splitter: | 1.4404/AISI 316L |

| Brazing Alloy: | BNi-2 |

| EX CERTIFICATIONS | |

| ATEX (Ex): | Zone 1: Group IIC or IIB, T2…T4 |

| ATEX (Exn): | Zone 2: II 3G Ex nA IIC T2…T4 Gc |

| IECEx (Ex): | Zone 1: Group IIC or IIB, T2…T4 |

| cCSAus (Ex1): | Class 1, Division 1: Group A, B, C, D or C, D, T2…T4 |

| For Ex1 the electronic is only available in aluminum housing. | |

| ATEX + IECEx + cCSAus triple approval (Ex3): | Zone 1: Group IIC or IIB, T2…T4 and Class 1, Division 1: Group A, B, C, D or C, D, T2…T4 |

| For Ex3 the electronic is only available remote and in aluminum housing. | |

| EAC (TR-CU): | Group IIC or IIB, T2…T4 |

| For EAC (TR-CU) the electronic is only available in aluminum housing. |

TRICOR® Coriolis Technology Ltd.

When you combine decades of experience with truly unique talents, great things can happen. TRICOR engineers have been intimately involved with the development and evolution of Coriolis flow instrumentation since the beginning. In fact, many of the critical patents for Coriolis technology bear our engineers’ names. The TRICOR Coriolis range of globally-certified flow measurement products are designed and engineered in Germany with support teams in the United States and Switzerland. Our state-of-the-art manufacturing facility in Karlsfeld, Germany is equipped with advanced calibration and test equipment that guarantees world-class performance and the highest-accuracy, delivering flow measurement solutions for the most demanding applications.