Mechanical completion is not our objective; complete and accurate safety coverage for our clients is the goal.

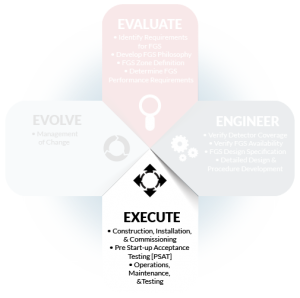

Microwatt has the tools and experience to ensure an optimized installation and operation of a Fire and Gas System through to a effective handover to the end user. Our successful track record of testing and commissioning procedures helps develop a steadfast facility commissioning plan and comprehensive schedule to meet our client needs.

Establishing milestones and identifying critical paths to accomplish the successful integration of commissioning activities have helped us become the company of choice for FGS projects. MicroWatt’s focus on safety and quality during design, procurement and construction phases right through to start-up ensure a successful project execution.

Establishing milestones and identifying critical paths to accomplish the successful integration of commissioning activities have helped us become the company of choice for FGS projects. MicroWatt’s focus on safety and quality during design, procurement and construction phases right through to start-up ensure a successful project execution.

Activities to be performed during office phase:

- Submission of marked-up P&ID by system

- Submission of detailed Pre-Commissioning/Commissioning execution plan

- Organization Chart

- Personnel deployment schedule

- Submission of method statement

- Testing methodology

- Acceptance requirements

- HSE implications

- Submission of punch-list statement

- Procedure and form to identify, record and correct damaged, incomplete and incorrect installations

- Procedure and form to identify equipment that is inaccessible or unsafe

- Submission of commissioning feedback to the design process

- P&ID review

- HAZOP review

- C&E diagram review

- Loop drawing review

- Submission list of commissioning spare parts and consumables

Activities to be performed during site phase:

- Mechanical completion

- Check of physical installation

- Check of electrical installation

- Pre-commissioning

- Punch listing equipment and installation

- Check instrument against data sheet

- Energize equipment

- Correct deficiencies

- Commissioning

- Develop and review specific operating instructions

- Program and setting of equipment

- Perform calibrations and instrument loop checks

- Conduct performance test

- Perform FGS alarms testing

- Perform interlocking system testing

Operation, Maintenance and Testing

Due to the complexity and extensive testing requirements of Fire and Gas systems, many clients rely on us for the routine maintenance of these systems to ensure safe and reliable operation. Our experienced service department has worked for countless operators, and has a number of long term service agreements.

Some of the services we provide include: Development of operating and test interval instructions, Development of calibration and function test procedures, Records keeping and interpretation, Troubleshooting, Repair, Mechanical restoration, Calibration and functional checks, Technological upgrades.

Contact Us to Learn MoreMicroWatt Controls

MicroWatt product offerings include design and manufacture of innovative Class 1, Div 1 flame and gas detection system solutions, industrial wireless SCADA and telemetry solutions including solar RTU packages, EFM packages, alarm call-outs, and level monitoring as well as a full range of calibration gases. From our facility in Calgary, Alberta, we provide products and services to many industries including Oil and Gas, Pipelines, Water Systems, Mining and Manufacturing; offering complete solutions to our Western Canada customers.