ANYmal X, Your Ex-Proof Inspector

ANYmal X Key Features

- Certified Explosion-proof

- Autonomous Mobility

- Super-human Inspection Intelligence

- Automated end-to-end Workflow

- IP67 Water & Dustproof

- Self-righting

- Obstacle avoidance

- Automatic docking

- Thermal camera & Ultrasonic microphone

- 3D Environment scanning

The World’s First Ex-Proof Legged Robot

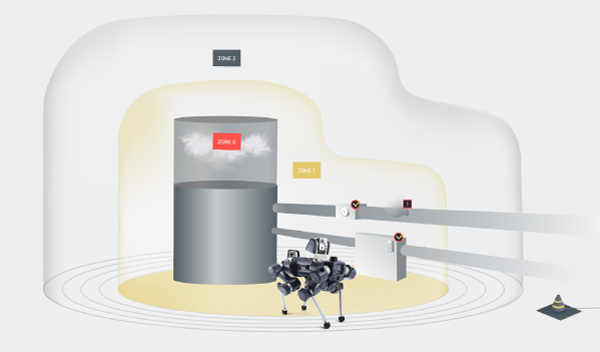

Ex-Proof Operations

ANYmal X provides autonomous robotic inspections in Oil & Gas and Chemicals facilities. The robot is certified for

operation in Zone 1 according to the IECEx and ATEX standards. The system is also fully IP67 ingress protected and

ready for long-term deployment in harsh outdoor environments.

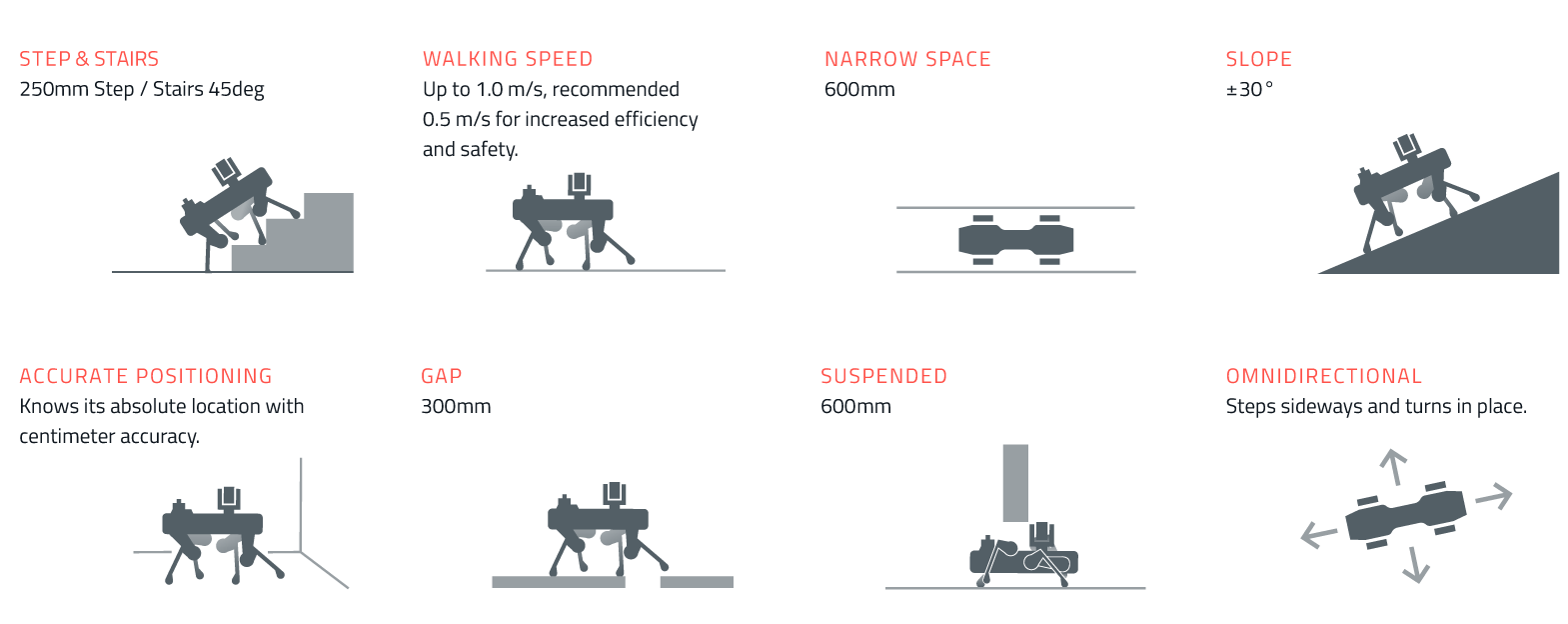

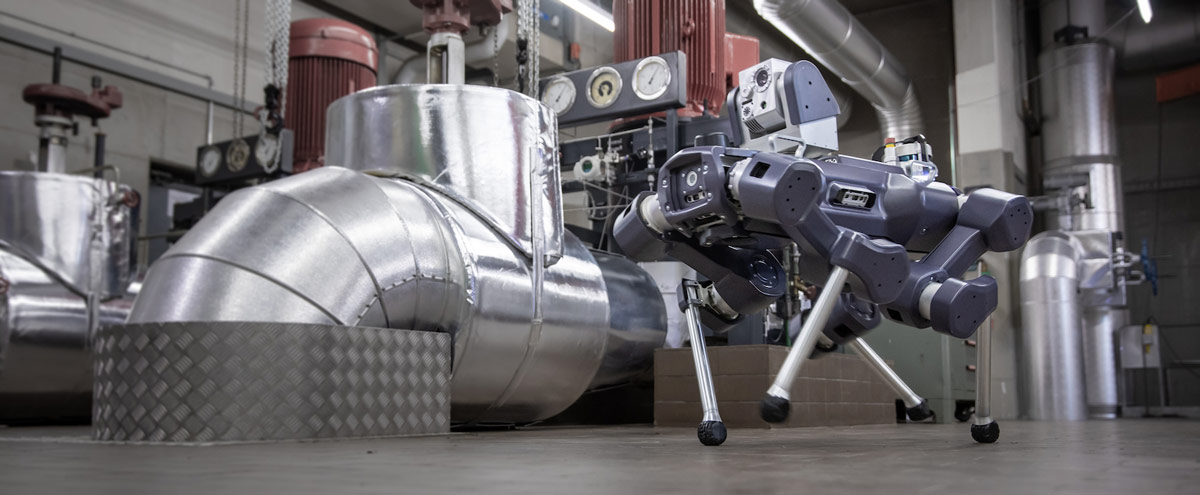

Extreme Mobility

ANYmal X’s legged design and AI-based mobility software provide unprecedented mobility and performance. Combined with its obstacle avoidance capabilities, the robot is ready for use in complex and dynamic environments. The robot reliably navigates any environment and traverses rough terrain with ease. ANYmal X completes even challenging missions requiring it to climb steep stairs, pass through narrow corridors, or conquer rocky, slippery, or wet surfaces.

Full autonomy

ANYmal X’s unparalleled ability to perceive and navigate its environment powers fully autonomous operation. Once it maps an environment, the robot remembers every detail and can dynamically plan the best route to perform its mission, even without an internet connection. The robot can avoid collisions, plan & re-plan paths, and recharge autonomously in a safe zone. All this together enables safe, efficient, and continuous autonomous operation.

Teach ANYmal X once where to go and what to do for repetitive inspection routines.

Import CAD / BIM

Import your existing CAD models to virtually set up inspection points, paths, and missions.

Navigation Waypoints

ANYmal X uses the points for autonomous navigation.

Inspection Points & Mission Setup

Inspection points are defined as a special navigation goal for the robot.

Collision Avoidance Modes

The robot employs multiple modes to avoid collisions and safely stop near cliffs.

Automated Safe Zone Charging

The docking station enables continuous autonomous operation and is also defined as a point of interest during setup of the facility environment.

Source: ANYbotics

Source: ANYbotics

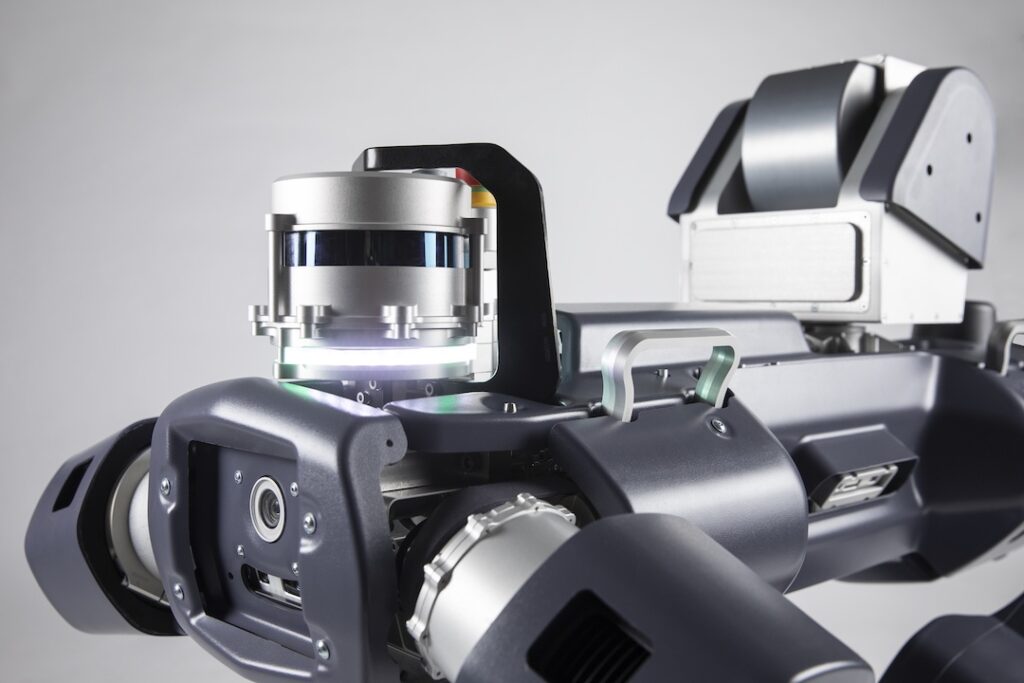

Intelligent Industrial Inspection

ANYmal X’s inspection payload provides visual, thermal, and acoustic insights for condition monitoring of equipment and infrastructure. The pan-tilt unit is used for scanning the environment around the robot and accurately positioning the built-in sensors for inspections of points of interest. AI-based inspection algorithms analyze the sensory data to interpret values, classify results, and detect anomalies.

Components

Zoom camera

The visual camera provides a 20× optical zoom to take clear images and videos at far distances at 4K resolution.

Thermal camera

The thermal camera provides precise temperature readings in a range of -20–500°C without physical interaction.

Spotlight

The LED spotlight is used to support visual inspections in low-light conditions.

Ultrasonic microphone

Directional microphone for recording acoustic measurements in the audible and ultrasonic frequency range.

Pan-tilt unit

The high-range motion of the pan-tilt unit together with the robot base motion positions the sensors to check hard-to-reach places.

Edge computer

Built-in computation analyzes and protocols sensor readings, eliminating the need for continuous network communication.

Capability Actions

Reading Instruments

A broad range of analog instruments and indicators can be digitized. Once trained on a type of instrument, the value or state is reliably identified.

Detecting Events

Unforeseen technical events can result in hazardous situations. Equipped with precision sensors, ANYmal X detects dangerous conditions in the environment and triggers a warning when required

Checking Health of Equipment

Early signs of operating problems are caught by examining the general health of the equipment. During the inspection, ANYmal X checks critical points for anomalies and reports severe problems immediately.

3D Environment Scanning

Industrial environments require continuous tracking of structural changes. ANYmal X supports operations by scanning and documenting 3d environmental data.

Inspection Reporting

Generate reports of inspection results, export results to data portals or digital twin, or see inspection results live in the GUI

Payloads

Inspection Payload

- Zoom camera

- Thermal camera

- Microphone

- Spotlight

- Range of motion Pan: ±165°, tilt: -90°/+90°

- Weight 6kg (13.2Ibs)

Gas Sensor Payload (Optional)

- Compatible models: Honeywell SensePoint, Drager PIR 3000

- Payload Max. 2 sensors

- Gas detection

- Electrical interface

Additional payloads available including BlackArc, Fluke acoustic camera and more!

Key Specs

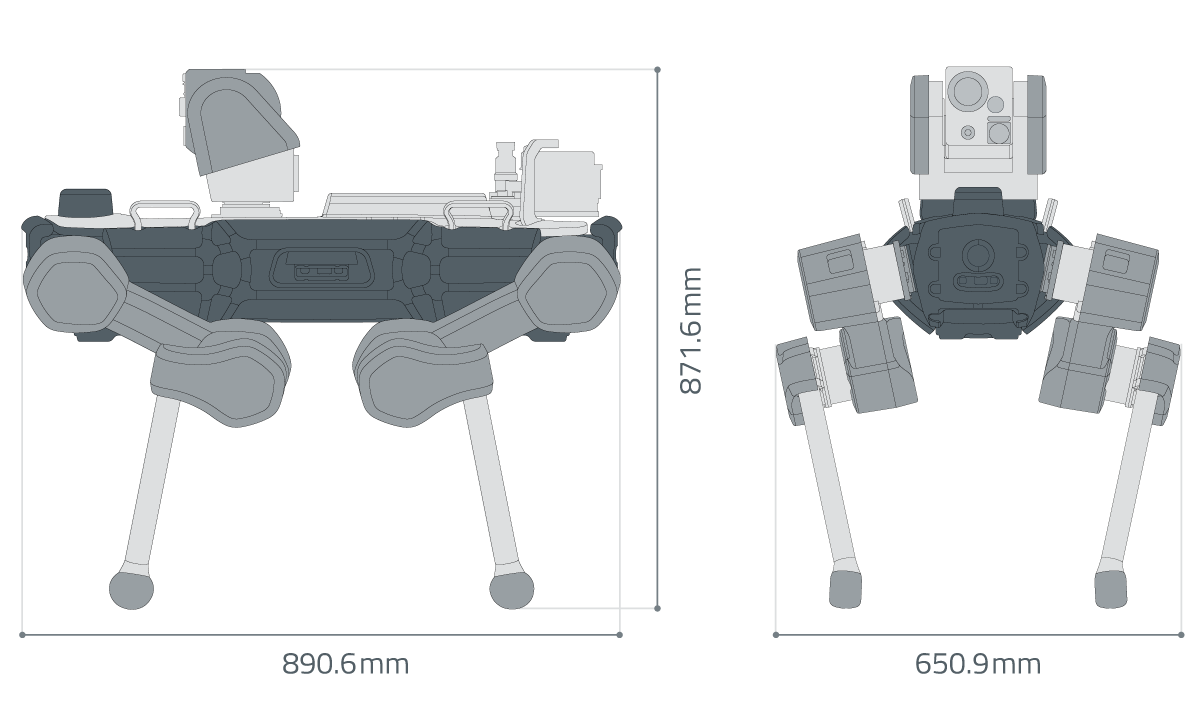

Dimensions:

Length: 891 (35.06 in)

Width: 651 mm (25.63 in) (default walking)

Height: 872 mm (34.31 in) (default walking) / 440 mm (17.33 in) (lying on ground)

Weight:

60.1 kg (132.5 lbs) with Inspection Payload and Gas Sensor

Obstacle Sensing:

0.3—3 m range, 87.3 × 58.1 × 95.3º depth FOV (Horizontal / Vertical / Diagonal), Class 1 Laser Product

Environment Mapping:

360° Lidar

Tele-operation Cameras:

1440 × 1080px cameras 110 × 76.5 × 117.7º FOV (Horizontal / Vertical / Diagonal)

Battery:

60—120 minute on a full charge

Operating system:

Ubuntu 20.04

Connectivity:

Wifi Built-in module 2.4 / 5 GHz, 802.11 ac wave2

Access point or client mode