Calgary, Canada – December 1st, 2025 In heavy industries—including metals processing, mining, oil & gas, and petrochemicals—the margin for error is razor thin. A single equipment failure can trigger cascading consequences: production stoppages, environmental hazards, and financial losses totalling millions. The real question isn’t whether you can afford to invest in reliability, but whether you can afford not to.

Calgary, Canada – December 1st, 2025 In heavy industries—including metals processing, mining, oil & gas, and petrochemicals—the margin for error is razor thin. A single equipment failure can trigger cascading consequences: production stoppages, environmental hazards, and financial losses totalling millions. The real question isn’t whether you can afford to invest in reliability, but whether you can afford not to.

Nondestructive Testing (NDT) has evolved dramatically. Once viewed as routine inspection methods, modern NDT technologies are now strategic tools that support predictive maintenance, asset integrity, and operational resilience. Think of these technologies as your plant’s sensory system—listening, watching, and analyzing so you can act before problems escalate.

From Reactive to Predictive: The Evolution of NDT

Traditional NDT methods such as ultrasonic testing, radiographic testing, and magnetic particle inspection remain essential. They detect flaws without damaging assets and ensure safety and compliance. However, these methods are typically “snapshot inspections,” limited to scheduled intervals. And in an environment where uptime is critical, that simply isn’t enough.

Modern NDT enables real-time monitoring, remote diagnostics, and advanced visualization. With continuous data streams, maintenance teams can predict failures, optimize planning, and reduce downtime—all without shutting down production. This shift moves inspections from occasional checks to a deeper understanding of asset behaviour over time.

The Advanced NDT Technologies Driving Change

1. Acoustic Imaging: Turning Sound Into Actionable Insight

Acoustic imaging transforms sound into a visual map. Using dense microphone arrays and advanced algorithms, these systems pinpoint leaks, vibrations, and anomalies—even in noisy environments.

Common Applications:

- Handheld acoustic cameras: Ideal for fast walkdown inspections.

- Fixed acoustic arrays: Used for permanent facility monitoring.

Industry Impact:

Metals facilities are reducing energy consumption by locating compressed-air leaks. Oil & gas operators are detecting gas leaks earlier, preventing shutdowns and improving safety.

2. Vibration Cameras: Seeing What Other Sensors Miss

Traditional vibration analysis requires accelerometers mounted to equipment. It works, but it is labour-intensive and costly—especially when each machine requires multiple contact sensors.

Vibration cameras offer a new approach by visualizing vibration patterns that are invisible to the naked eye. These systems detect subtle movements and convert them into clear, actionable data.

Benefits:

- No equipment shutdowns required

- No physical sensor attachment

- Rapid detection of imbalance, misalignment, or looseness

Cost Savings:

A single vibration camera can evaluate multiple pumps, motors, and fans in minutes—reducing the need for dozens of contact sensors and lowering hardware and labour costs.

Why It Matters:

Faster root-cause analysis, reduced downtime, and improved asset reliability.

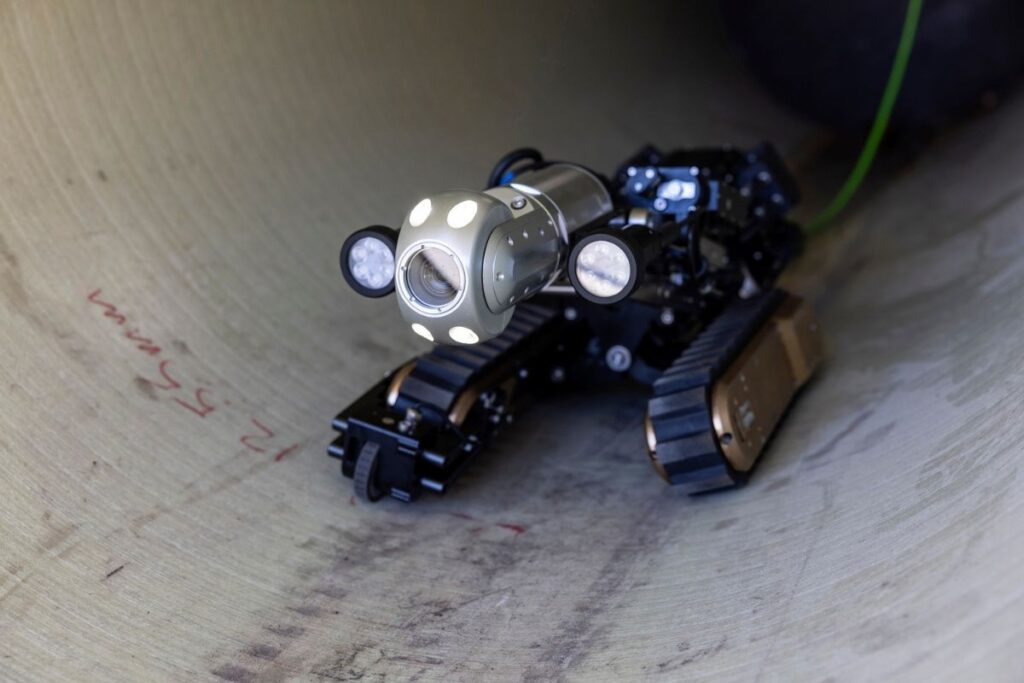

3. Robotic Inspection Platforms: Safe Access to Hazardous Zones

Robotic inspection platforms equipped with cameras and NDT sensors can safely operate in environments that pose significant risks to workers, including:

- Confined spaces inside tanks and vessels

- Explosive atmospheres on offshore platforms or petrochemical plants

- High-temperature areas near furnaces or reactors

- Radiation zones within nuclear facilities

By allowing remote inspections, these robotic systems reduce human exposure, improve compliance, and support continuous production without requiring shutdowns.

4. Magnetic Crawlers: Multi-Sensor Inspection Powerhouses

Modern magnetic crawlers are far more than cameras on tracks—they are modular, heavy-duty inspection platforms built for hazardous environments and vertical surfaces. With strong magnetic adhesion and high payload capacity, they can support multiple advanced NDT tools in a single deployment.

Sensor Integrations Include:

- Ultrasonic Testing (UT) probes for corrosion and wall-thickness measurement

- LiDAR systems for 3D mapping and digital twins

- Laser scanners for dimensional analysis

- Eddy current sensors for surface and near-surface flaw detection

- High-definition cameras with tilt, zoom, and LED lighting

- Manipulator arms for foreign-object retrieval

- Custom NDT sensor configurations for specialized inspections

Why It Matters:

Magnetic crawlers consolidate multiple inspection methods, reduce downtime, and provide a comprehensive asset integrity assessment.

Example: Complete Inspection of a Metal Storage Tank

Traditionally, inspecting a large steel storage tank required scaffolding, rope access, and extended shutdowns. With a multi-sensor magnetic crawler, the workflow changes dramatically:

- Deployment: The crawler magnetically adheres to the tank wall and climbs remotely.

- Visual Inspection: High-definition cameras evaluate welds and surface conditions.

- Dimensional Analysis: LiDAR and laser scanners generate a 3D digital model.

- Corrosion Monitoring: Ultrasonic probes measure wall thickness at multiple points.

- Surface Integrity: Eddy current sensors detect cracks and surface flaws.

- Data Integration: All results are streamed to an asset management platform for reporting.

Result: A complete inspection in hours instead of days—with no scaffolding, no confined-space entry, and no production interruption.

5. Permanently Installed Ultrasonic Sensors: Always-On Monitoring

These sensors are mounted directly onto critical assets to track wall thickness, corrosion rates, and cracking 24/7. Continuous ultrasonic monitoring is essential for predictive maintenance, especially on pressure vessels, pipelines, and high-risk equipment.

Future Outlook: Where NDT Is Headed

Over the next decade, NDT will continue to integrate with digital and automated technologies, including:

- AI-powered analysis for faster and more consistent defect detection

- Digital twins that model asset lifecycles and predict future failures

- Cloud platforms that centralize inspection data and enable remote decision-making

- Integrated robotics for continuous facility-wide inspection

- Net-zero and emissions-reduction initiatives supported by early leak detection and process optimization

Advanced NDT will play a central role in industrial digital transformation, asset integrity management, and sustainable operations.

Conclusion

Advanced Nondestructive Testing isn’t just about inspections—it’s about confidence, compliance, resilience, and protecting people. For leaders in heavy industry, investing in these technologies means fewer surprises, safer operations, and a strong competitive advantage in a high-risk environment.

If you’re experiencing a shift toward predictive maintenance—or exploring where to begin—our team would be interested in hearing what challenges you’re facing.