In our last article, “Robots can effectively overcome real world challenges” we looked at some of the issues facing industrial workplaces and discussed how robots can overcome and sometimes solve problems that seemed previously insurmountable.

Artificial intelligence, precision of operation, productivity, safety, and reporting are just some of the functions and features that robotics can utilize in assisting your industrial workplace. These are no longer just the fancy of science fiction authors; rather, these are tools that are currently available and can benefit your operations immediately. Today we would like to introduce you to one robot that can handle many of these tasks and more.

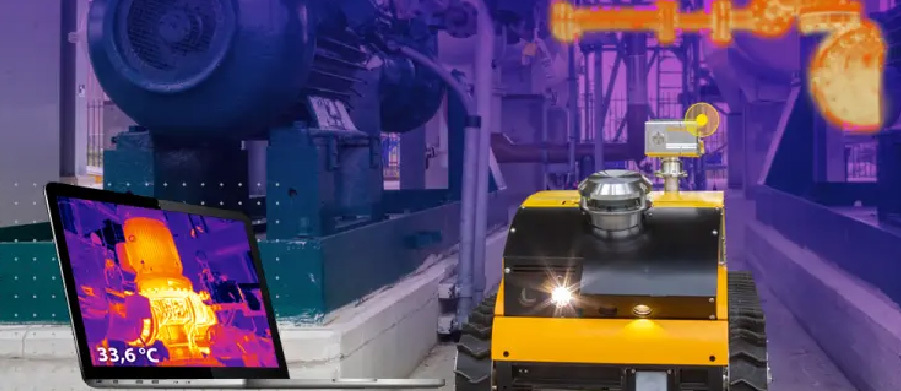

Meet The ExR-2

The fully autonomous ExR-2 robot from EX Robotics is the robot that can handle many of these tasks and more. Coming standard with many features that already make it functional for most environments, this unit also offers many options to customize it for your work environment.

Unless robots are certified for hazardous operation; industrial, specifically Oil & Gas, environments cannot make the best use of them. The good news is that the ExR-2 is manufactured with IECE & ATEX zone 1 certifications; these are transferable to Class/Division certifications that we use in North America, and we are currently working with local regulatory bodies to get these completed. Now let us delve into what features these robots have and how they can work for you.

Features

The ExR-2 is designed as a track-mounted, crawling robot. It can travel up and down 35-degree slopes, and the track system makes it perfect for dealing with multiple surfaces. Here are some examples of terrain that the unit can handle:

- Roads

- Slabs

- Gravel

- Grating

- Grass

- Climbing up and down 10cm ledges

Coming out-of-the-box at roughly 100 Kg, this unit has a 2km travel range and the battery can last 3 to 8 hours on a single charge. Charging is completed by plugging into a 120v or 240v plug or by having the robot automatically return home and dock itself on the induction charger. The induction charger also has a hazardous approval so the ExR-2 can continuously reside in a hazardous area saving time and battery for missions.

Expert Navigation

The ExR-2 is designed to be fully autonomous, and to achieve this it has a powerful LiDAR and AI/ML computer on board. The LiDAR allows the robot to have situational awareness of its environment and, combined with the internal AI, can autonomously navigate complex environments. Obstacle detection, obstacle avoidance and mission re-adjustment are simple tasks with these tools.

These features work together to enable the ExR-2 to recognize its environment and adjust the robots’ mission when required. Obstacles that are hazards can trigger the robot to send warnings to the control room and wait for further directions. This situational awareness makes the daily operation of the robot more simple and more useful. Imagine if an obstacle is a man down; the ExR-2 will then notify the control room and take immediate action while providing local situational environmental data to aid in the rescue operation.

Data Collection

The ExR-2 also utilizes its built-in onboard technologies to create a Digital Twin. This is a three-step process that creates a 3D world that can be stored in the cloud for use offline or in real-time. Step 1 involves driving the ExR-2 through a facility and scanning the environment in 3D using the onboard LiDAR. Step 2 is a manual operation where the operator teaches the ExR-2 the planned route and any inspection points along the way.

Data collection can include gas detection, video, acoustics, vibration monitoring, pictures, infrared detection and much more through one of its analog or digital inputs. Step 3 is setting the ExR-2 on its autonomous mission and collecting all the necessary data continuously.

These three steps ensure that your facility is available remotely as a Digital Twin and all data is stored with it. This data can then be merged with other data sets to create a full picture that you can store in public or private clouds. Digital Twin is a powerful feature that allows you to bring the professional to the facility without the time, cost and safety issues involved with in-person visits.

Next Level Visuals

The ExR-2 also comes equipped standard with a stationary drive camera and a telescoping and panning, digital zoom inspection camera. The drive camera allows for real-time video in a front-forward facing view. This can be used with manual operation or while a robot is performing a pre-programmed, automated mission.

As well, the inspection camera is available for real-time use manually or on a mission. The ability to pan and zoom allows the camera to inspect gauges, foreign objects, potential problem spots or anything else the operator wants to have a look at. For a real-world example, the ExR-2 can run a mission and the inspection camera can work with the internal AI to inspect gauges and then determine if they are within acceptable range.

When something is inspected and determined to be out-of-range the system can then notify the operator and appropriate action can then be taken. All the videos and pictures are taken in high-definition formats however they are wirelessly transferred to the operator in lower quality to keep the speed of operation up. Later, when the robot is resting and charging, the unit will upload the high-quality images and store them in case they are required for later review.

Communication Capabilities

The ExR-2 also comes equipped with high-quality LED lighting to illuminate work environments and a microphone to listen in when required. Communication in some of these remote environments can be difficult. The ExR-2 comes equipped with an antenna and built in 4G/LTE with Wi-Fi available as an option.

When the Wi-Fi option is added, the system will automatically default to the selected primary communication method but also alternate whenever required. Some environments can have spotty reception, and this will help eliminate communication outages. This allows for smoother real-time operation while ensuring that the best data is still captured and available whenever required.

These features alone make the ExR-2 a valuable tool for any industrial environment. The ability to run missions keeping your workers safe from hazardous environments is enough to justify the operation of these units.

Endless Possibilities

Consider further some of the other features that the ExR-2 can be equipped with; Thermal IR Camera, Point gas detectors, Fixed Infrared Gas Detector, VOC Gas Detector, Acoustic Detectors, vibration and temperature monitoring and many others. Some of these options can be mounted on an elevating mast for additional applications. The combination of features is virtually endless, making the ExR-2 the most capable and useful robot available on the market today.

The ExR-2 is available to purchase outright, lease, RAAS (Robot as a service) or Maas (Mission as a service). Which scenario is right for your facility depends on how you are planning to utilize your unit. Perhaps you have other requirements that we have not yet considered, the ExR-2 has additional analog and digital inputs that we can consider using for your specific technology or application. Contact us today to arrange a live demonstration.

Want to Learn More?

Take a look at our Robotics